Have you ever wondered how fridge magnets stick for years without losing power? Or why your wireless phone charger works so efficiently? The answer often lies in ferrite magnets – the unsung heroes of everyday tech. Let’s break down what they are and why they matter, in plain language anyone can understand.

Directory Listing:

What are Ferrite Magents?

Ferrite is a type of non-metallic magnetic material that was developed in the 1940s. It is a metal oxide with ferrimagnetic properties, meaning it can produce a magnetic field. Compared to metals or alloys, ferrite has much higher electrical resistivity and better dielectric (insulating) properties.

Ferrite’s magnetic qualities make it ideal for use in high-frequency applications. It also has high magnetic permeability, meaning it can easily become magnetized at high frequencies. As a result, ferrite is commonly used in fields involving weak electrical currents at high frequencies.

However, ferrite has a low saturation magnetic induction (Bs) compared to pure iron, typically only one-third to one-fifth of that of pure iron. This limits its use in applications requiring high magnetic energy density, such as low-frequency and high-power electrical systems.

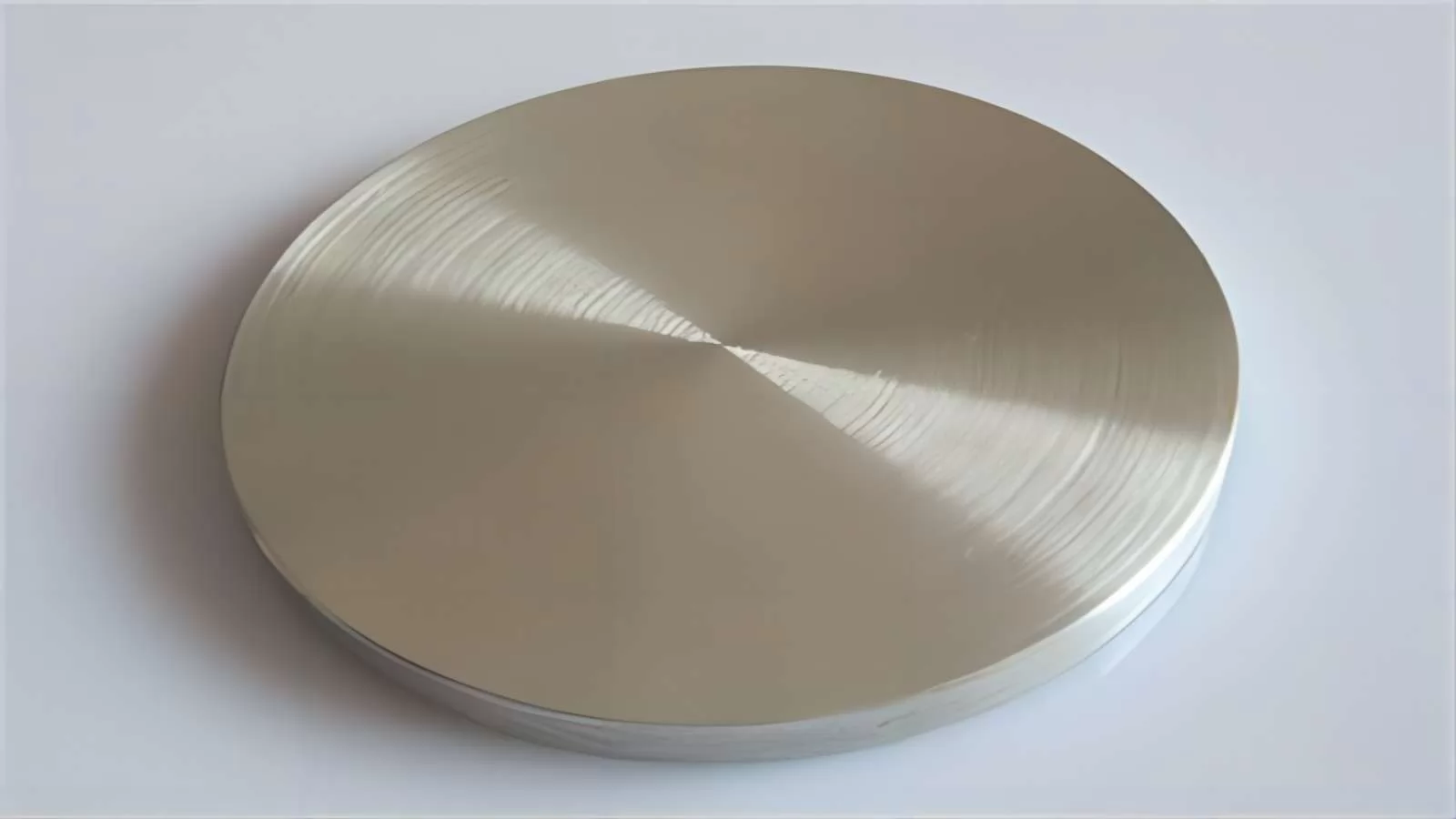

How Ferrite Magnets Are Made: From Rust to Magnet in 4 Steps

- Mix the Ingredients: Iron oxide and ceramic powder are blended together.

- Press into Shapes: The mix is pressed into discs or blocks using powerful machines.

- Bake at Extreme Heat: The pieces are heated to 1,300°C.

- Zap with Magnetism: A strong magnetic field is applied to turn them into real magnets.

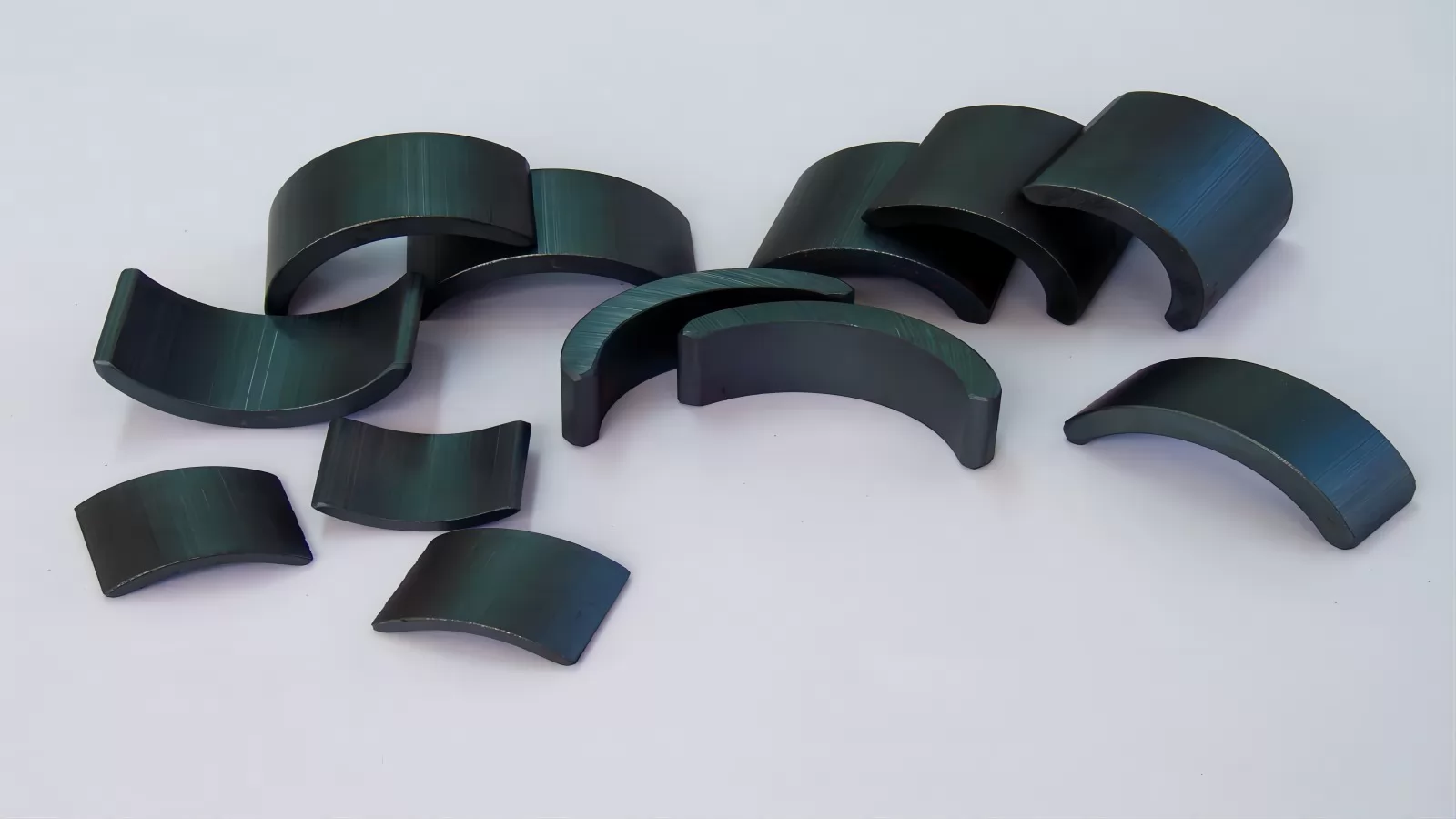

Two Types of Ferrite Magnets:

-

Hard Ferrite Magnets

- Used in: Fridge magnets, car motors

- Superpower: Never lose their magnetism

- Secret recipe: Iron oxide + barium

-

Soft Ferrite Magnets

- Used in: Phone chargers, power adapters

- Superpower: Control electricity flow silently

- Weakness: Can’t hold magnetism long

_1722063735_WNo_1600d900.webp)

Key Characteristics:

Ferrite magnets are known for several key features that make them valuable for a wide range of applications:

-

Moderate Magnetic Strength

While not as powerful as neodymium magnets, ferrite magnets have enough magnetic strength for many everyday uses. This makes them ideal for devices that don't need extreme magnetic force. -

Resistance to Demagnetization

One of their standout qualities is their excellent resistance to demagnetization. They can maintain their magnetic properties, even when exposed to external magnetic fields. This stability is crucial for long-term use in both industrial and consumer products. -

Temperature Resistance

Ferrite magnets can work effectively at high temperatures—up to 250°C—without losing their magnetic strength. This makes them perfect for use in environments where other magnets might fail. -

Corrosion Resistance

Unlike neodymium magnets, ferrite magnets are naturally resistant to corrosion. They don’t require protective coatings and can withstand exposure to moisture and chemicals. This makes them especially useful in outdoor and marine environments. -

Cost-Effectiveness

Ferrite magnets are made from abundant and inexpensive raw materials, mainly iron oxide, which makes them a cost-effective option. The production process is also relatively simple and low-cost, adding to their affordability. -

Durability

While ferrite magnets are hard and brittle, they are durable and resistant to mechanical wear over time. However, they should be handled carefully to avoid cracking. Despite their brittleness, they remain a robust choice for many demanding applications.

Common Applications:

Ferrite magnets are widely used across various industries due to their versatile properties. Here are some of the most common applications:

-

Electric Motors

Ferrite magnets are frequently used in electric motors, where their moderate magnetic strength and stability are crucial for efficient performance. They are commonly found in automotive applications, powering components like windshield wipers and starter motors.

-

Audio Industry

In the audio industry, ferrite magnets are essential in the production of loudspeakers. Their ability to convert electrical energy into sound makes them perfect for this application, ensuring clear and consistent audio output. They are also used in microphones to generate the necessary magnetic field for capturing sound accurately.

-

Magnetic Separators

Ferrite magnets are used in magnetic separators, which remove magnetic materials from non-magnetic ones. This application is critical in industries such as recycling and mining, where efficient material separation is key to operational success.

-

Consumer Electronics

Ferrite magnets are found in various consumer electronics, such as televisions and computer monitors. They are used in deflection yokes to control the direction of the electron beam in cathode-ray tubes. While this technology is becoming less common due to the rise of LCD and LED screens, it still showcases the flexibility of ferrite magnets.

-

Magnetic Assemblies

Ferrite magnets are often used in magnetic assemblies for tasks like holding, lifting, and separating. Their strength and stability make them ideal for applications where reliable performance is essential.

-

Sensors and Meters

In sensors and meters, ferrite magnets are used to measure various parameters, such as speed and position. Their accuracy and dependability make them a valuable component in providing precise readings.

Advantages and Disadvantages of Ferrite Magnets

Advantages:

- Affordability: Ferrite magnets are cheaper to produce than many other types of magnets.

- Stability: They maintain their magnetic properties over a wide range of temperatures and operating conditions.

- Resistance: They are resistant to demagnetization and corrosion, enhancing their longevity in various environments.

Limitations:

- Magnetic Strength: Ferrite magnets are not as strong as rare-earth magnets like neodymium.

- Brittleness: They are hard and brittle, making them susceptible to cracking under mechanical stress.

- Size and Weight: For applications requiring high magnetic strength, ferrite magnets tend to be larger and heavier compared to neodymium magnets.

Conclusion

Ferrite magnets are versatile and economical magnets suitable for a variety of applications due to their moderate magnetic strength, excellent temperature and corrosion resistance, and cost-effectiveness. While they may not offer the same magnetic strength as neodymium magnets, their durability and stability make them a reliable choice for many industrial and commercial uses. When selecting magnets for your project, considering ferrite magnets can provide a balance of performance and affordability, especially in environments where high strength is not the primary requirement.

If you need a reliable manufacturer, then it is recommended to contact ketai ,ketai is a new high-tech enterprise specializing in R&D, production, processing and sales of NdFeB permanent magnet materials

_1722060505_WNo_1600d900.webp)